Research

- Development of nano-scale wiredrawing: Molecular Dynamics Analysis of defect behavior in iron and steel wire

- Atomistic Study on the Performance of Electrolytes in Lithium Ion Batteries(LIB): Evaluation of Li+ diffusion, viscosity and ionic conductivity

- Plastic Deformability and Strength Evaluation of Silicon Based Hard Brittle Material (SiC)

- Mechanical Transmission in Hierarchical Structure of Biological Fibrillar Materials (Collagen / Cellulose Nano-sized Fibers): Twisting Force and Its Energy Transmission from Micro to Macro

- Multi-scale Modeling and Analysis of Solid Materials: Collaboration between Molecular Dynamics and Macroscopic Particle Method (Peridynamics Theory)

- Nano-scale Tribology and Plastic Deformation: The Effect of Nano-sized texturing on Friction

- Computer Simulation Methodology for Dynamic behavior of Solid Materials

- Universality of Structures based on Mechanical Function: Development from Molecular Structures to the Concept of Tensegrity

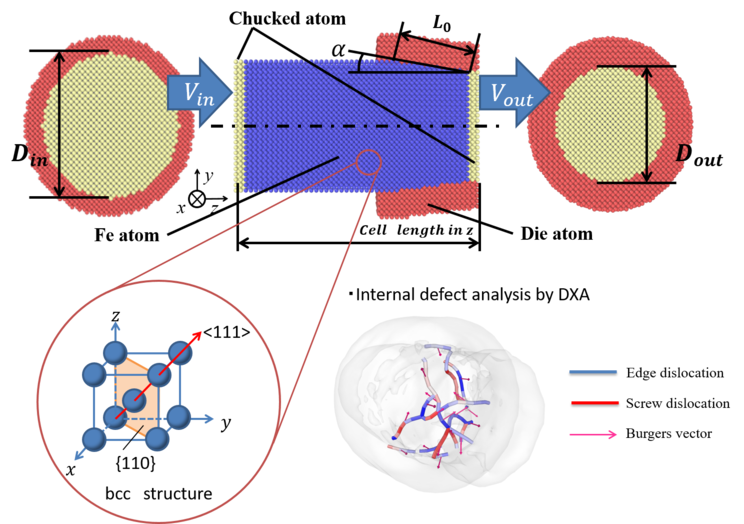

Development of nano-scale wiredrawing: Molecular Dynamics Analysis of defect behavior in iron and steel wire

Nowadays, concern for global environmental problems such as air pollution and exhaustion of resources has been increasing. Reduction of environmentally hazardous substances and improvement of fuel consumption are becoming a big issue in the problems. In order to deal with these problems, high performance and high strength are strongly demanded for steel wires and wire rods. In recent years, along with the advance in technology, downsizing of steel wire has been strongly motivated. For example, needs of fine wire in the medical field are increasing very much. Under such circumstances, attention is being paid to the innovation of wire drawing processing, which leads to higher strength of wire rods.

Wire drawing is a conventional type of plastic working, in which a workpiece (usually metal) is passed through a conical die and finished into a bar or thin wire having the same cross section as the die exit cross. For an advantage of wire drawing, it can obtain significant improvement in strength, particularly in the tensile direction as well as needed elongation. Consequently it is used in a wide range of manufacturing fields such as steel cords of tires, piano wire and bridge cable. It is commonly said that mechanical properties of materials are largely involved in microscopic structures furnished in processing, and analyses of materials at the atomic level are indispensable. We are simulating the atomistic phenomena of nano-sized metallic wire which has yet seen by any experiment and are trying to elucidate the mechanism for high strength.

As for strengthening the steel wire, fine grain strengthening, solid solution strengthening, or dislocation strengthening can be cited. Therefore, lattice defect, i.e. dislocation, is a dominating factor contributing to high strength of the material. We clarify the behavior of dislocation in drawn wires and tryto benefits their high strength.